How does underfloor heating work?

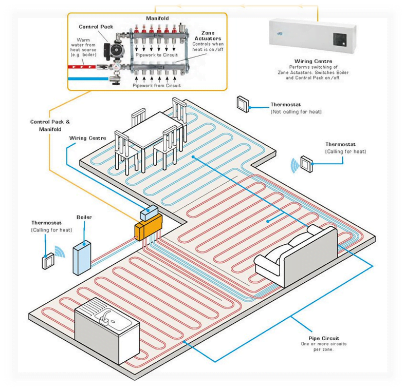

- A boiler or heat pump supplies heat to the system by heating the water (that is pumped through it.

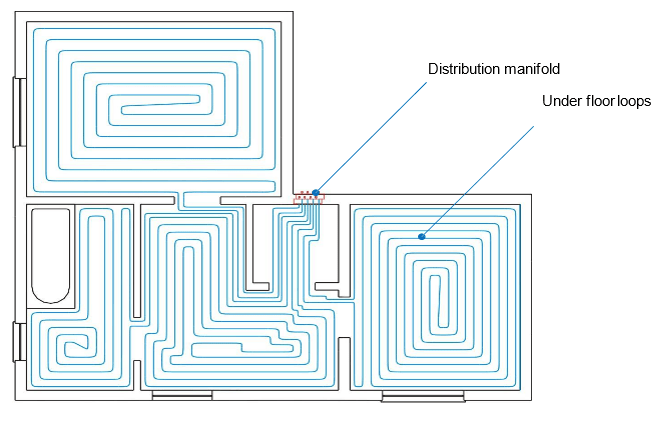

- Primary pipework carries the heat from the heat source to the manifold(s). Manifolds distribute the heat to the underfloor pipe loops.

- Pipe loops, with hot water flowing through them, heat the floor, typically at least 1 loop for every 20 m2 of heated floor area.

- Controller switches the heat source on and off, and directs the heat to where it is needed to heat the rooms to the desired temperature.

- Underfloor heating requires a flow temperature of around 50°C flow and 40°C return.

- Feel comfort by controlling the temperature of each room with a Thermostat or by your smart home application.

Underfloor Heating System Characteristics:

- THERMAL WELL-BEING

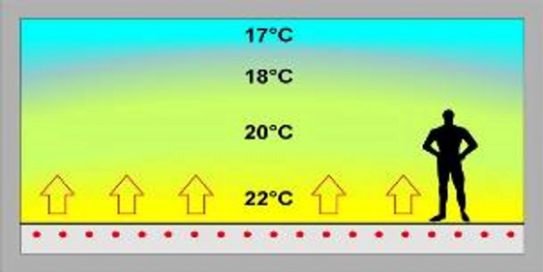

Temperature distribution with floor heating system

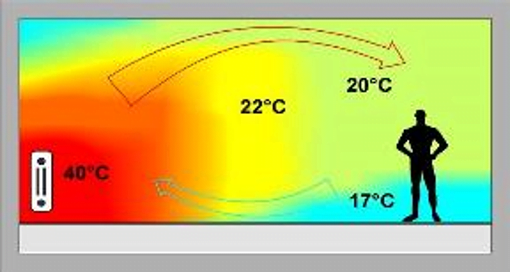

Temperature distribution with convective system

-

- Absence of convective motions.

- Vertical distribution of temperature.

- The temperature distribution is the nearest to the ideal curve and therefore “thermal well- being”.

- ENERGY SAVING

… To save about 25% or more thanks to:- Low temperature of the heating fluid.

- Elevated heating surfaces.

- Reduced heat loss.

- Thermal well-being at lower room temperatures (1°C less than traditional systems).

- HYGIENIC CONDITIONS

- There is no transport of dust normally caused by the convective motions.

- No combustion of dust that creates stains on walls.

- No risk of irritation of air tracts.

- ARCHITECTURAL ADVANTAGES

- No architectural limits linked to the presence of radiators / fan heaters.

- Possibility of using all available space.

- Minimum architectural impact in buildings such museums and old villas.

Main Components of Central Heating System with Radiators

Wall Hung Gas Combi Boiler (with flue system)

A simple and modern style

- The new MYNUTE S has been specifically designed for a trouble-free installation.

- automatic temperature control in heating mode.

- IPX5D electrical protection.

- Primary heat exchanger in copper.

- Double air inlet (right and left side) allowing to fit easily in the existing flues.

- 9 liters expansion vessel, able to manage installations with high water content.

- 3-speed circulator, 5 meters.

- Intuitive and easy-to-use control panel with backlight digital display.

- Suitable for connection with Beretta remote control panels (as option).

- Compact dimensions and low weight allow MYNUTE S to be installed anywhere.

- Dimensions (H x L x W): 740 x 400 x 332 mm

- Weight: 33 Kg

Distribution and Control, Caleffi, Italy*

Dirt Separator

Manifold

Automatic Filling Unit

Radiator Valve

Lock Shield Valve

Double Ball Valve

Fittings

Thermostatic Head

Thermostatic Head

* Some items may not be included in the final system.

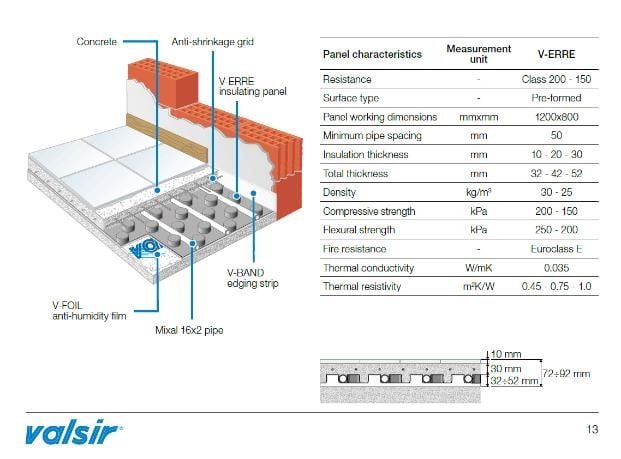

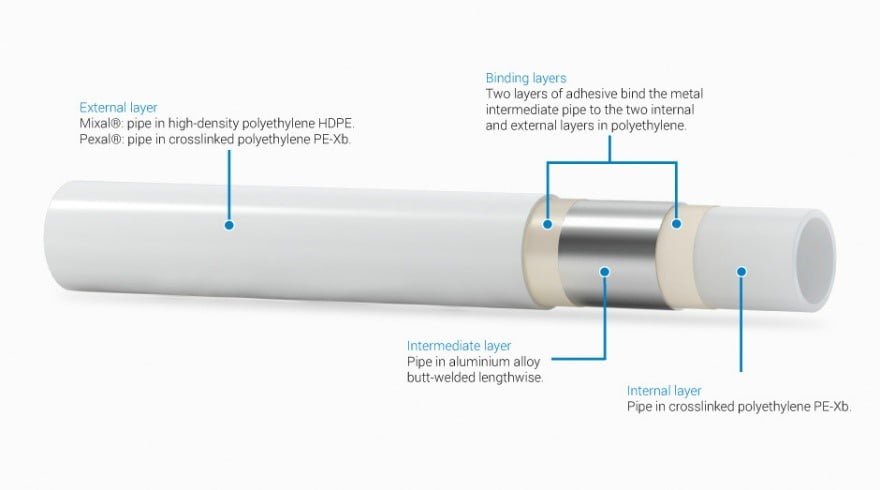

Piping (between the manifold panel and the radiators), Valsir, Italy

- Heat performance

- The presence of the aluminum layer, its thickness and position, result in excellent heat conductivity characteristics.

- With Mixal®pipes it is possible to carry out floor heating systems with higher heat outputs.

- In fact, the greater conductance generates higher temperatures on the pipe surface as compared with all-plastic pipes (PE-X and PERT) and this advantage is reflected, for example in the possibility of obtaining relatively low supply temperatures.

- The greater performance of Mixal®pipes compared with all-plastic pipes means greater system output at equal flow conditions. An example: the 16×2 Mixal® pipe has the same thermal output as the 17×2 PE-X pipe.

- Mechanical behavior

- The mechanical characteristics of the Mixal® pipes make them ideal for use in floor heating systems. The bending radius corresponds to 2.5 times the pipe diameter and the circular section at the bend remains constant.

- The pipe, once bent, remains in the desired position like a metal pipe; hence the use of anchor clips is not required as with all-plastic pipes.

- Barrier against oxygen and UV rays

- The inner layer in aluminum acts as a perfect barrier against the passage of gaseous molecules thus avoiding the danger of corrosion due to oxygen infiltration and damage caused by exposure to UV rays